|

|

|

|

| |

|

| |

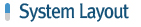

System Configuration Chart System Configuration Chart

|

| |

|

| |

System Advantages System Advantages

- 32bit, 150MHz DSP Board.

- Digital Control by TCP/IP

- Up to 6 Actuator Control

- Servo Valve Control Servo Motor Linear Motor Control

- High rate Control(15KHz)

- SACT, Operating & Data Acquisition

- Stand Alone or PC Operating

- TCP/IP

System Specification System Specification

- PID Close Loop Controller for Hydraulic Servo Valve & Servo Motor

- Multi Channel Expandable, up to Channel per board

- Large LCD Display

- Control by TI 150MHz. 32bit DSP board

- Data Acquisition by TCP/IP

- Signal Conditioning 5 KHz C.F. Measuring Amplifier

- Limit Funcion of force, Displacement

- Stand alone or PC Operation

| Parameter |

Specification |

| Servo control |

Channel |

1 to 6channel per board |

| Test object |

Any transducer (Load, Displacement, Strain) |

| Parameter |

Вұ10v, 0-50mA |

| Frequency |

0.001 TO 1000Hz |

| Control |

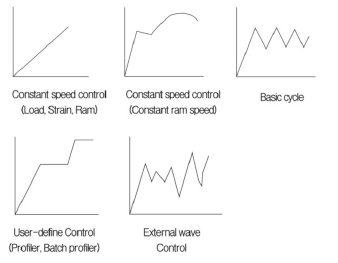

Basic wave (sine, ramp, triangle etc)

User-define mode

External spectrum loading mode

Profile (one, mult, Batch profile) |

| Test Mode |

Force, displacement |

| Control loop |

15KHz |

| Main Cpu |

TI 150MHz, 32bit DSP Board |

| Input |

Analoge |

6 Channel, Вұ10V |

| Digital |

4 Channel |

| Encoder |

2 Channel (TTL or Line drive) |

| Output |

Analog |

Вұ10V, 6 Channel |

| Digital |

4 Channel |

| Data Acguisition |

TCP/IP |

| Signal Conditioner |

Strain amplifier

5KHz, 0.03%, built in lowpass filter. |

| Dimension |

450(W)Г—279(D)Г—135(H)mm

19вҖі rach mounted type (option) |

| Power input |

220V, 60Hz |

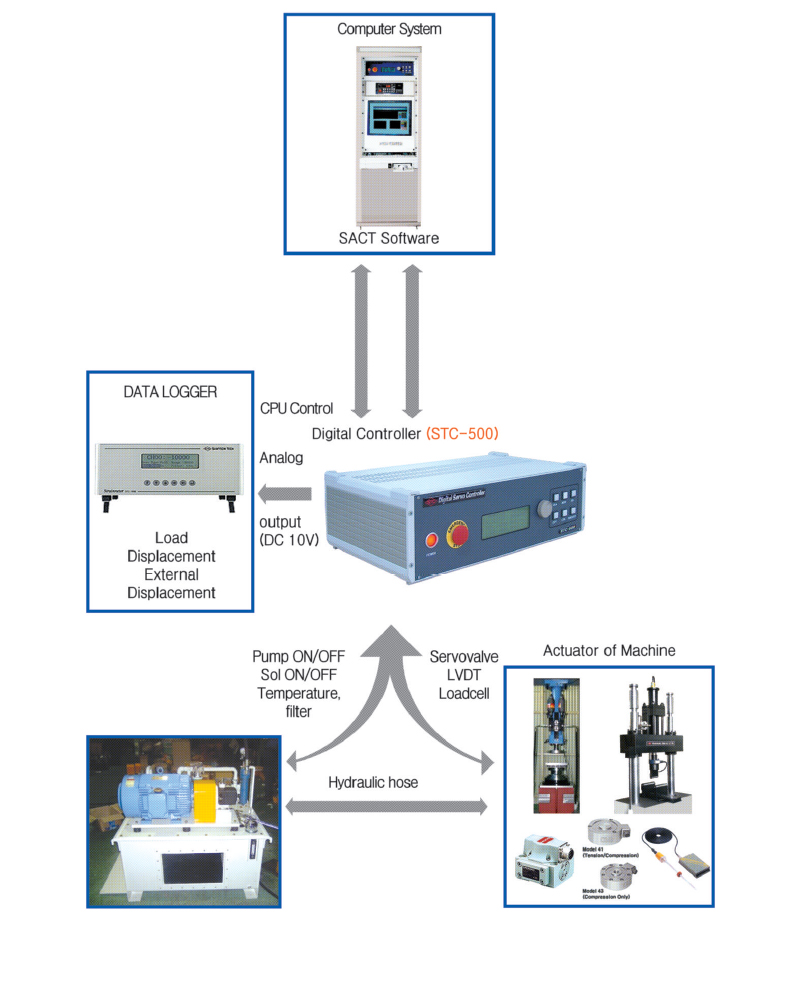

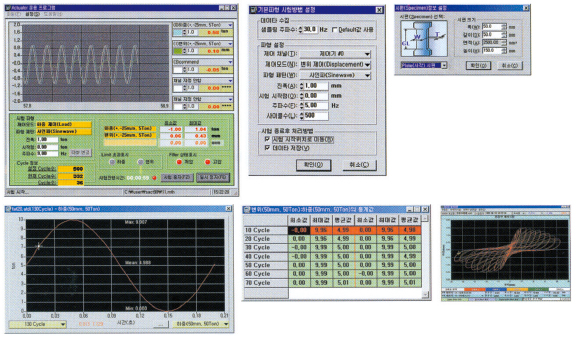

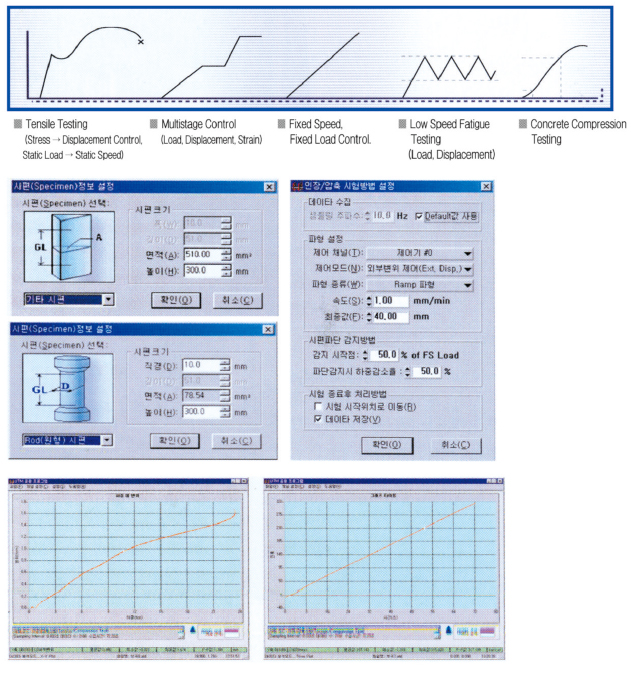

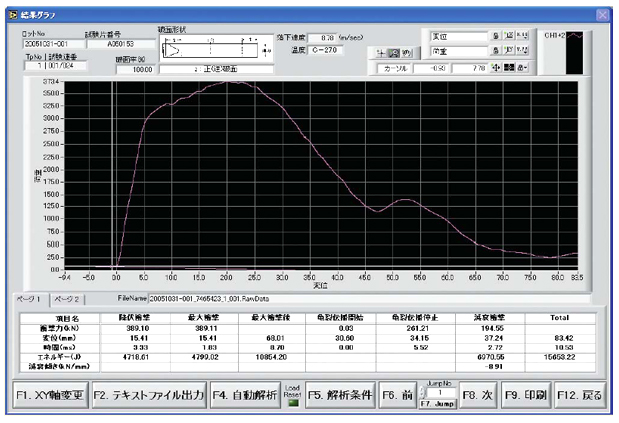

SACT PROGRAM SACT PROGRAM

- Multi Channel Control(Max. 18ch)

- Windows XP Operating

- Excel, ASC в…Ў, File Convert

- Stress, Stroke Graphic

- Cycle Count

- LAN(TCP/IP) Data Acquisition

- S/N Curve, Strain(%) Young Modules, Poisson's ratio

- Random & Spectrum Loading Mode(Option)

Control Mode Control Mode

Analysis Analysis

|

| |

|

| |

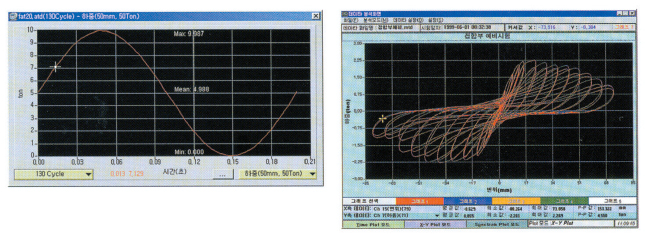

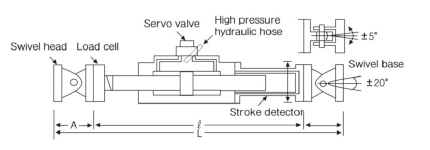

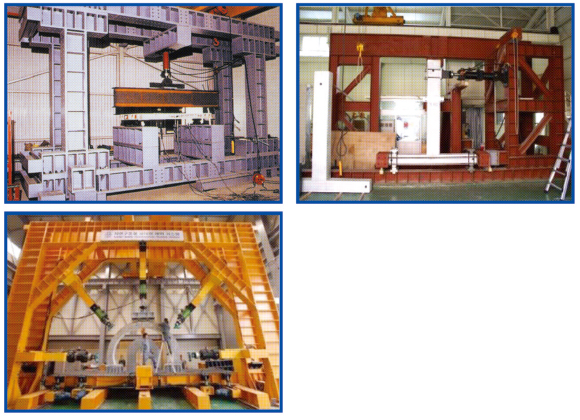

Hydraulic Servo Actuator Hydraulic Servo Actuator

- Hydraulic Servo Actuator System

Main Use Main Use

- Strength test of construction, engineering, other structures with the temporary control volume

(load, displacement, strain) by the various waveforms

- Behavior test of structure following earthquake and the like

- Dynamic load simulation received during the running of automobile and vehicle.

- Durability test on dynamic load received during the operation of heavy equipment component

- Durability experiment of load received from the large vehicle running on the ground,

underground materials (major facility like electricity, gas and others) and building surface

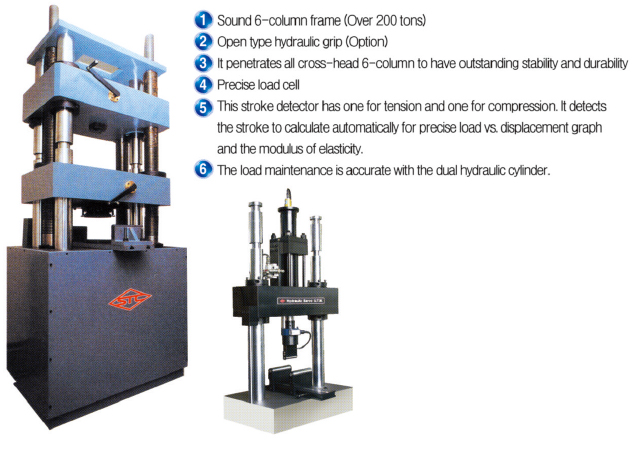

- System Advantages

- For a domestically produced good, it performs more thorough A/S in comparison to the foreign

product with many supply performance records of up to 3,000 tons.

- STC-500 hydraulic servo control board, developed in several years, can test from 0.01-100Hz

and the direct control is done on PC for load, stroke and stain or stand alone.

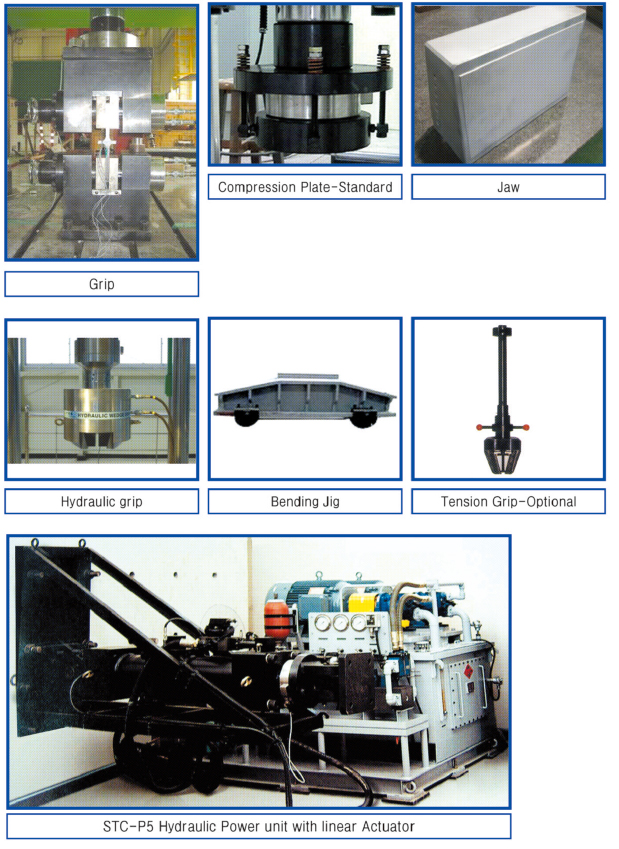

- Swivel header, swivel base, compression plate, PC system and N.l16bit A/D, 16bit D/A

transducer are supplied with standard product.

- For high density (Вұ0.5%) and durability, the major measuring devices use the products of

worldwide makers including SENSOTEC load cell, SANTEST LVDT, MOOG servo valve, N.I

16bit A/D, 16bit D/A transducer.

- The jig device for performing various tests is promptly supplied.

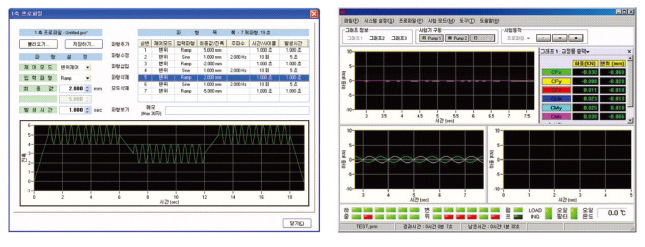

- Software SACT program has a variety of models and is convenient for use. It works on a PC

that performs the control and the data acquisition at the same time. Load and stress vs.

displacement graph, load and stress, displacement vs. time graph, and load, stress,

displacement vs. time graph are shown on monitor for graphic in real time simultaneously with

the test. The test is performed while observing the result value to save and print. When

necessary for amendment during the use, the up-grade is easily done.

- Dynamic and static strain meter (option) for 16 bit is supplied in low price to precisely

measure the displacement, load, vibration, strain and the like.

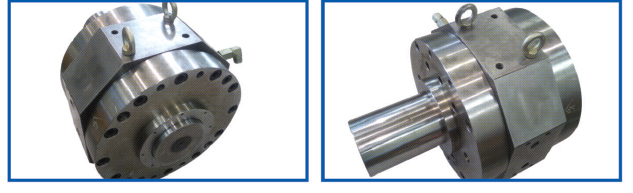

Liner Actuator Liner Actuator

Actuator Actuator

- Liner Actuator

Dynamic

Actuator

|

Static

Actuator |

| Type |

capacity

(kN) |

Stroke

(mm) |

Size |

Type |

capacity

(kN) |

Stroke

(mm) |

Size |

| в„“ |

L |

в„“ |

L |

| STC-10D |

Вұ100 |

Вұ100 |

1,000 |

1,600 |

STC-10S |

Вұ100 |

100

300 |

600

750 |

1,200

1,350 |

| STC-20D |

Вұ200 |

Вұ100 |

1,200 |

1,800 |

STC-20S |

Вұ200 |

150

300 |

750

850 |

1,300

1,650 |

| STC-50D |

Вұ500 |

Вұ150 |

1,450 |

2,250 |

STC-50S |

Вұ500 |

150

300 |

800

900 |

1,600

1,750 |

| STC-100D |

Вұ1,000 |

Вұ150 |

1,800 |

2,600 |

STC-100S |

Вұ1,000 |

150

300 |

900

950 |

1,700

1,850 |

| STC-200D |

Вұ2,000 |

Вұ200 |

2,000 |

2,500 |

STC-200S |

Вұ2,000 |

300 |

1,100 |

2,050 |

| STC-500D |

Вұ5,000 |

Вұ250 |

2,300 |

3,000 |

STC-500S |

+5,000

-3,000 |

500 |

1,500 |

2,000 |

- Rotary Actuator

- Vane Type : Single vane(Low-capacity)

- Double vane(Hign-capacity)

- Torque capacity:500NВ·m, 5KNВ·m, 10KNВ·m,25KNВ·m, 50KNВ·m

- Rotation

- Static:100'

- Dynamic:90'

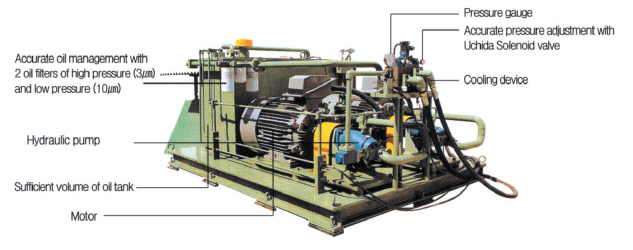

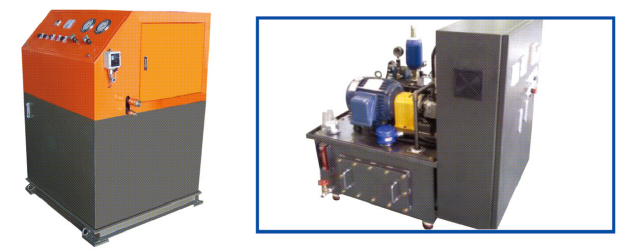

Hydraulic Power Unit Hydraulic Power Unit

- Hydraulic Power Unit

- Specifications

| Type |

Flow(в„“/m) |

Motor |

Cooling(в„“/m) |

|

| Dynamic |

Static |

| STC-P1 |

11 |

5.5kw |

10 |

|

STC-10S/STC-20S/STC-50S |

| STC-P2 |

19 |

11kw |

20 |

STC-10D/STC-20D |

STC-50S/STC-100S |

| STC-P3 |

60 |

22kw |

40 |

STC-20D/STC-30D |

STD-200S |

| STC-P4 |

120 |

22kw x 2 |

75 |

STC-30D/STC-50D |

|

| STC-P5 |

162 |

37kw x 2 |

150 |

STC-50D/STC-100D |

|

| STC-P6 |

228 |

55kw x 2 |

200 |

STC-100D/STC-200D |

|

| STC-P7 |

324 |

75kw x 2 |

300 |

STD-200D |

|

Hydraulic Pump Unit Hydraulic Pump Unit

Hydraulic Power Unit Hydraulic Power Unit

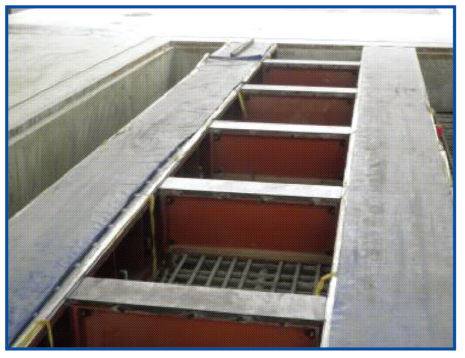

- jig

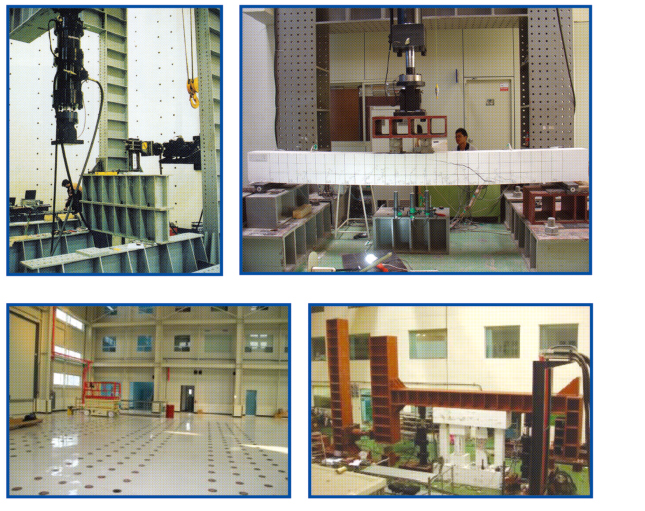

System Application System Application

- Structrul Test Lab

- Structrul Test Lab

- Motor muffler Test

Frame & Jack Frame & Jack

- Reaction Frame

- Hydraulic jack

Power pump function

Order-manufacture in addition to this dimension (hollow style, etc.)

Capacity

(tf)

(Compression/Tension) |

Stroke(mm) |

Load

Cell

|

Hydraulic

Pump |

| 30

/ 50 |

150

/ 300 |

30

Ton, tension/compression |

combined

manual |

| 50

/ 25 |

150

/ 300 |

50

Ton, tension/compression |

combined

manual |

| 100

/ 50 |

150

/ 300 |

100

Ton, tension/compression |

combined

manual |

| 200

/ 100 |

150

/ 300 |

200

Ton, tension/compression |

combined

manual |

|

| |

|

| |

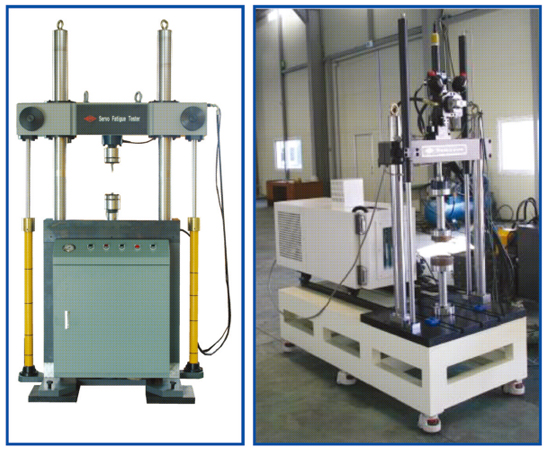

Hydraulic Servo Fatigue Tester Hydraulic Servo Fatigue Tester

- Hydraulic Servo Fatigue Tester Machine

Fatigue tester is equipped with low loading type hydraulic servo actuator on the loading frame that is sound and easy for operation. And it is the newest model that is appropriate for research and development, and is guaranteed for fast test speed, accurate control, precise measurement and durability.

This system is structured with loading frame, actuator, hydraulic unit (including servo valve), accumulator, servo control plate, PC system *16 bit A/D, 16bit D/A, card loaded) and control and data acquisition program.

- Loading Unit(Model:SF-5M)

It uses the hydraulic pump and Moog servo valve of sufficient flow rate to enable the experiment of high frequency and realization of fast test speed.

The loading unit with sound and simple cross head vertical movement has a fine durability.

SACT Program that realized the accurate control and precise measurement simultaneously has abundant and various functions.

- SACT Ver.2 Operating Program

- Window XP

- For static and dynamic fatigue test

- Graphic of load, vs displacement

- Cycle count

- Analysis:S-N Curve/Elastic modulus/Energy

- Test mode:Basic/User define/Externa wave

- Digital Servo Controller

| Control object |

Load, Displacement, Strain etc. |

| Large size LCD display |

|

| Control mode |

Basic, user define, External wave loading by sine, ramp, triangular etc |

| Frequency |

0.001 to 1000 Hz |

| Control loop |

P.I.D close-loop |

| A/D channel |

16 |

| 32bit DSP Board |

150MHZ |

| Data acquisition |

NI 16 bit PCI card |

| Signal conditioning |

HBM 5 KHz C.F Measuring Amplifier |

| Control Method |

Stand alone or PC Control |

- Specifications

(Type) |

SF-0.5M |

SF-1M |

SF-2.5M |

SF-5M |

SF-10M |

SF-25M |

Load(kg)

Stroke(mm) |

500

Вұ25 |

1,000

Вұ25 |

2,500

Вұ25 |

5,000

Вұ25 |

10,000

Вұ25 |

25,000

Вұ25 |

Load Accuracy (%) |

Within

Вұ0.5% |

| Displacement

Accuracy (%) |

Within

Вұ0.5% |

Loading

Frame |

Type |

Cross-head

movement by hydraulic cylinder |

Between

Column

(mm) |

450 |

650 |

Testing Space (mm) |

400 |

500 |

| Dimension (mm) |

300X450 |

400X650 |

| Pump

Unit |

Model

Flow Rate

(в„“/min)

Motor(kW) |

|

SP-1

3.4

0.75 |

SP-2

5.6

1.5 |

SP-3

9.5

2.2 |

STC-1

11

5.5 |

STC-2

38

11 |

STC-3

57

22 |

| Servo

valve (в„“/min) |

3.4 |

5.6 |

5.5 |

11 |

38 |

57 |

| Load

Cell |

Tension

and compression combine

purpose

with Вұ0.1% Flat type |

| Stroke

Detector |

Non-Contact

Displacement Transducer |

Torsion Fatigue Testing Machine Torsion Fatigue Testing Machine

- Torsion Fatigue Testing Machine

- Specifications

| Model |

STC-RT200 |

STC-RT500 |

STC-RT1000 |

STC-RT2000 |

STC-RT5000 |

| Rotary Actuator |

| Rated torque (kg-m) |

Вұ2 |

Вұ5 |

Вұ10 |

Вұ20 |

Вұ50 |

| Linearity |

Вұ0.1% |

| Angular Displacement

Transducer |

| Angular |

Вұ60В°, Вұ90В° |

| Linearity |

Вұ0.1% |

| Test Bench (mm) |

2,400(L) x 600(W) |

2,500(L) * 650(W) |

| Max. Specimen Length (mm) |

1.400 |

| Servo valve (Moog) |

G761

(63L/min) |

G761

(63L/min) |

G761Г—2

(120L/min) |

J072

(228L/min) |

| Hydraulic Pump Unit |

STC-P3(60L/min) |

STC-P4

(120L/min) |

STC-P5

(228L/min) |

| Digital Servo Controller |

STC-500 |

| Operating Software |

SACT Ver.2, SAS data acquisition

software |

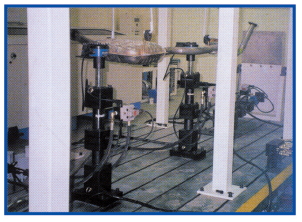

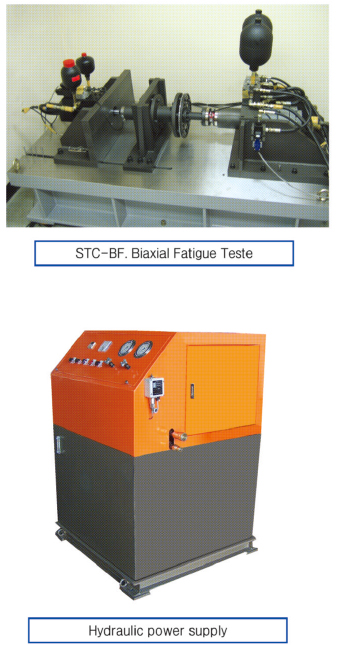

Biaxial Fatigue Tester Biaxial Fatigue Tester

- System Advantages

- Combined stress of the axial load and torsional torque in same or in optional different phase

- Actuator

- Linear Actuator:5,10,50,100 kN

- Rotary Actuator:200,500,1000,2000kg-m

- Consist of:Frame unit, Linear Actuator, Rotary Actuator,

Hydraulic Power unit, 2 axis Servo controller,

Software and Tension jig

|

| |

|

| |

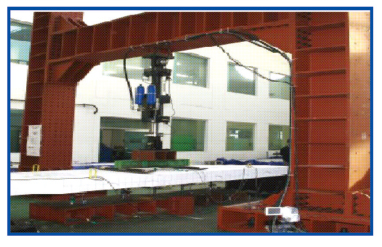

Hydraulic Servo Structural Testing Machine Hydraulic Servo Structural Testing Machine

- System Advantages

Program Program

- Control mode

Hydraulic Servo Structural Testing Machine Hydraulic Servo Structural Testing Machine

- Specifications

| Model |

STC- LS100 |

STC- LS200 |

STC-LS500 |

STC-LS1000 |

| Loading Unit |

| Max Load |

| Static(KN) |

1000 |

2000 |

5000 |

10000 |

| Dynamic(KN) |

750 |

1500 |

3000 |

5000 |

| Testing Height(mm) |

3000 |

5000 |

7000 |

10000 |

| Table Size(mm) |

1200Г—900 |

1300Г—1000 |

2000Г—1500 |

2500Г—2000 |

| Testing Speed |

0.001 to

200mm/sec (Depend on Hydraulic power

unit) |

| Testing Frequency |

0.001 to 30Hz |

| Servo Actuator |

| Type |

Double Acting, One Rod

(Optional Hydrostatic bearing type) |

| Max load(KN) |

Вұ1000 |

Вұ2000 |

Вұ5000 |

Вұ10000 |

| Stroke(mm) |

300 |

300 |

400 |

500 |

| Load cell(KN) |

Вұ1000 |

Вұ2000 |

Вұ5000 |

Вұ10000 |

| Accumulator |

4L, 10L(Depend on Hydraulic

power unit) |

| Servo valve |

Moog 63L ~ 150L/min

(Depend on required testing speed) |

| Stroke detector(mm) |

300 |

300 |

400 |

500 |

| Option |

Hydraulic tension grip |

- Digital Servo Controller

| Control

object |

Load, displacement,

strain etc. |

| Large size LCD display |

|

| Control mode |

Basic, user define,

External wave loading

by sine, ramp, triangular etc |

| Frequency |

0.001 to 1000 Hz |

| Control loop |

P.I.D colse-loop |

| A/D channel |

16 |

| 32bit DSP Board |

60MHz |

| Data acquisition |

NI 16 bit PDI card |

| Signal conditioning |

HBM 5 KHz C.F Measuring

Amplifier |

| Control Method |

Stand alone or PC

Control |

- SACT Ver.2 Operating Program

- System Application

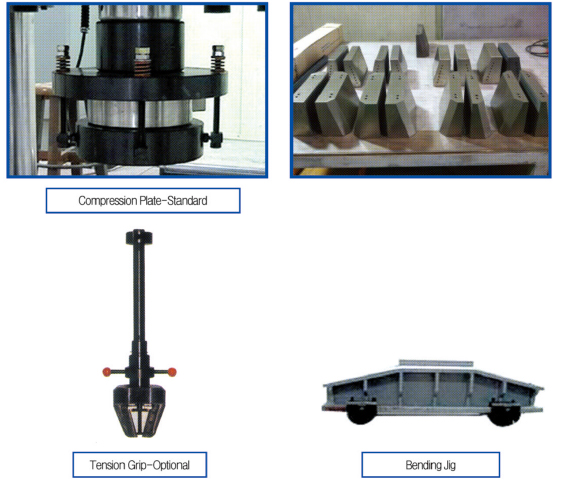

Tester & Accessories Tester & Accessories

Foundation Foundation

Parts Parts

|

| |

|

| |

Universal Testing Machine Universal Testing Machine

- Loading unit

- Specifications

Model |

STC-US10 |

STC-US25 |

STC-US50 |

STC-US100 |

STC-US200 |

STC-US300 |

| Maximum

capacity (tonf) |

10 |

25 |

50 |

100 |

200 |

300 |

| Load

(tonf) |

0.01

~10.00 |

0.01

~25.00 |

0.01

~50.00 |

0.01

~100.00 |

0.01

~200.00 |

0.01

~300.00 |

| Load

Accuracy (%.F.S) |

| Sensitivity

(Kgf) |

| Displacement

accuracy(%.F.S) |

|

|

|

|

|

|

|

Flow

rate of servo valve

(в„“/min) |

Actuator

capacity

(в„“/min) |

| Oil

filter (гҺ•) |

Cooler

<Option>

(в„“/min) |

|

|

|

|

|

|

|

Optimal

tension distance

(mm) |

| Table

size (mm) |

| Stroke

of ram (mm) |

| Diameter

of compression diameter

(mm) |

| Width

of bending punch(mm) |

|

|

|

|

| 800 |

| 900X650 |

| 250 |

| ОҰ160 |

| 100 |

|

| 1,050 |

| 900X750 |

| 250 |

| ОҰ220 |

| 120 |

|

| 1,100 |

| 1,250X850 |

| 300 |

| ОҰ220 |

| 150 |

|

| Strain

speed (mm/min) |

Cross-head

movement speed

(mm/min) |

| Hydraulic

pump |

|

|

|

|

|

|

|

Machine

weight

(Approx)(ton) |

Machine

size

(Approx)(mm) |

|

| 1.5 |

700(w)X

500(D)X

1,300(H) |

|

| 2.1 |

800(w)X

500(D)X

1,800(H) |

|

| 2.5 |

880(w)X

600(D)X

1,900(H) |

|

| 3.2 |

800(w)X

650(D)X

2,000(H) |

|

| 6.2 |

1,050(w)X

850(D)X

2,300(H) |

|

| 9 |

1,350(w)X

850(D)X

2,400(H) |

|

Hydraulic

grip

|

- |

- |

- |

OPEN

TYPE

(Optional) |

OPEN

TYPE

(Optional) |

OPEN

TYPE

(Optional) |

| Control

plate |

STC-302

Controller, UTM98 program |

Structural Structural

- Specifications

Model |

STC-USS100 |

STC-USS200 |

STC-USS300 |

| Maximum

capacity (tonf) |

100 |

200 |

300 |

| Load (tonf) |

0.01-100.000 |

0.02-200.000 |

0.03-300.000 |

| Load Accuracy (%/F.S) |

Вұ0.5 |

Вұ0.5 |

Вұ0.01 |

| Tension distance (mm) |

1800 |

2200 |

2700 |

| Table size (mm) |

2100пјҠ700 |

3000*1000 |

3500*1200 |

| Stroke of ram (mm) |

250 |

250 |

300 |

| Diameter of compression (mm) |

ОҰ160 |

ОҰ220 |

ОҰ220 |

| Test speed (mm/min) |

110 |

110 |

110 |

| Cross-head movement speed (mm/min) |

220 |

220 |

220 |

| Hydraulic pump |

3.7 |

5.5 |

7.5 |

| Flow rate of servo valve(в„“/min) |

9.5- |

9.5- |

15- |

| Controller |

STC-5WS |

STC-5WS |

STC-5WS |

| Oil filter (гҺ•) |

3 |

3 |

3 |

| Air cooling system |

|

|

|

| Hydraulic grip |

Optional |

Optional |

Optional |

| Machine weight (Approx) |

6 |

11 |

15 |

| Machine size (Approx)(mm) |

2100(W)*700(D)*4500(H) |

3000(W)*1000(D)*5210(H) |

3200(W)*1200(D)*5800(H) |

Program Program

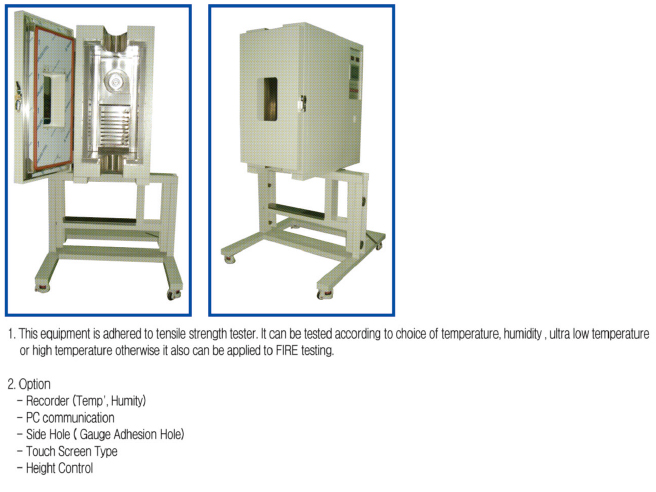

UTM Chamber UTM Chamber

Model / Spec |

ACE-HC-

96H |

ACE-HC-150H |

ACE-HC-250H |

ACE-HC-96L |

ACE-HC-150L |

ACE-HC-250H |

| In Size (W/D/H) |

400*400*600(mm) |

500*500*600 |

500*500*1000 |

400*400*600 |

500*500*600 |

600*600*800 |

| Out Size (W/D/H) |

500*700*700(mm) |

600*800*700 |

600*800*11000 |

500*700*750 |

600*800*750 |

600*800*1150 |

| In Material |

SUS 304 Plate |

| Out Material |

SUS 430 Plate Painting |

| Temp' |

Program Controller |

| Temp' Range |

RT+10в„ғ~ 250в„ғ MAX |

-170в„ғ~ 400в„ғ MAX |

| Temp' Accuracy |

300в„ғatВұ3в„ғ |

-70в„ғatВұ50в„ғ |

| Heater |

Kanthal Pipe Heater |

| Thermo-Couple |

Pt 100О© |

| Power |

AC 220V 1ОҰ 60Hz |

| Watts |

2.8kW |

3.5kW |

4.8kW |

3.0kW |

3.8kW |

5.5kW |

|

| |

|

| |

System Advantages System Advantages

- High speed

- High Accuracy

- High Stiffness

- High speed data acquistion

- Safety

- Co-operated with MAEKAWA, Japan

- System consist

Main frame, striker, striker up, down equipment, striker lock-release

equipment, specimen supplier, controller, data acquisition, software, safety

equipment chamber(option)

- Main frame

1)Type:drop weight type

2)Max impact energy:5KJ, 10KJ, 50KJ, 100KJ, 300KJ

3)Drop height:1 to 10meter(variable)

4)Striker:500Kg to 3000kg(variable)

5)Load detector:Loadcell

- Striker

1)Striker guide column

2)Base:High stiffness

3)T-slot Base(Option)

4)TUP:Can be used in chamber with loadcell

5)Striker up, down

-chain hoist

-capa:enough capa for striker weight

-speed:dual speed

-height setting accuracy:Ўҫ2mm

-height detector:Laser

6)Striker lock&release:Electronic magnetic type

7)Speciment Support equpment

8)Impact speed detectorLaser/photo diode type Accuracy:less than Ўҫ

0.1%

9)Impact load detector

-Loadcell included TUB

-capa:150% of max energy

-accuracy:less than Ўҫ0.5%

-signal conditioner:DC96A:200Kz, auto balance, lowpass filter, dual output (Volt, Output)

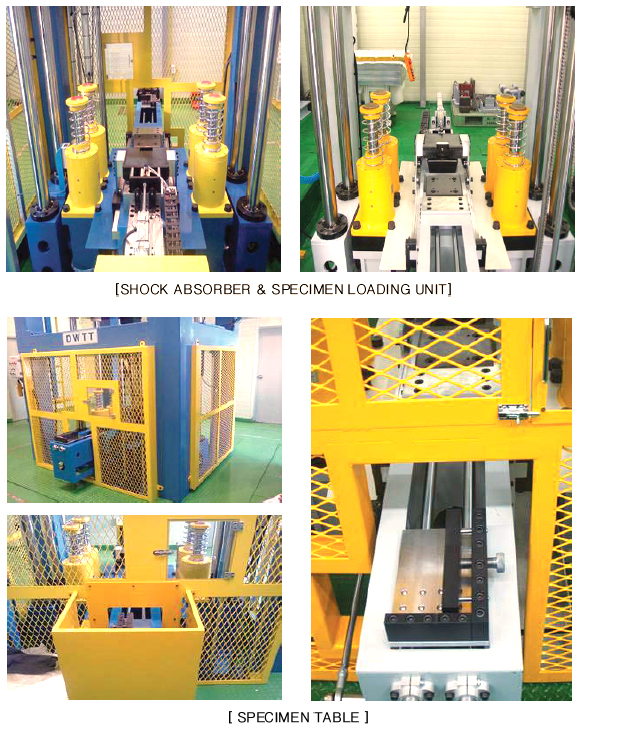

Specification Specification

4.Controller 4.Controller

1)19"rack

2)Manual & auto mode

3)Safety:Alram, emergency stop button, Door interlock

4)PLC:Mitsubishi Melsec

5)Magnetic controller included

5.Software

1)Windows XP/7

2)Function:Speciment input, measure, storage, analysis & report

3)Disply:speciment, conditionof test, test start etc

4)Graph:Load vs Time, Load vs disp, energy, overay, filtering etc

5)P.C system

6. Safety equipment

1)Safety fence

2)Saddle:up to top of tester

|

| |

|

| |

| |

|